KEY FACTS

- Research into natural materials for environmental protection

- Alfalfa and fungal residues as resource-saving alternatives

- Iterative improvement of the manufacturing process

- No-waste tea light design inspired by Victoria Amazonica

- Alfalfa and fungal residues as resource-saving alternatives

- Iterative improvement of the manufacturing process

- No-waste tea light design inspired by Victoria Amazonica

RESEARCH THESIS

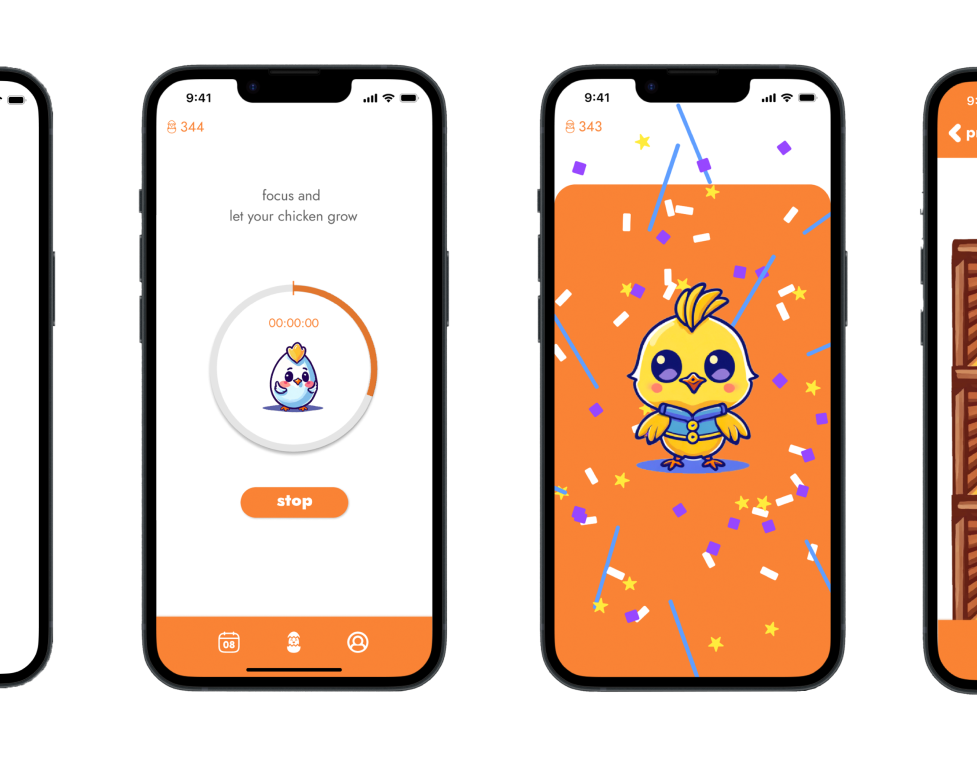

"Examination and investigation of experimental shape formation with bio-materials as a sustainable alternative to plastic"

The research thesis aims to explore the potential of natural materials as a sustainable alternative for our environment. Organic materials such as alfalfa and mushroom residues of the king oyster mushroom make it possible to use resource-saving materials that are biodegradable.

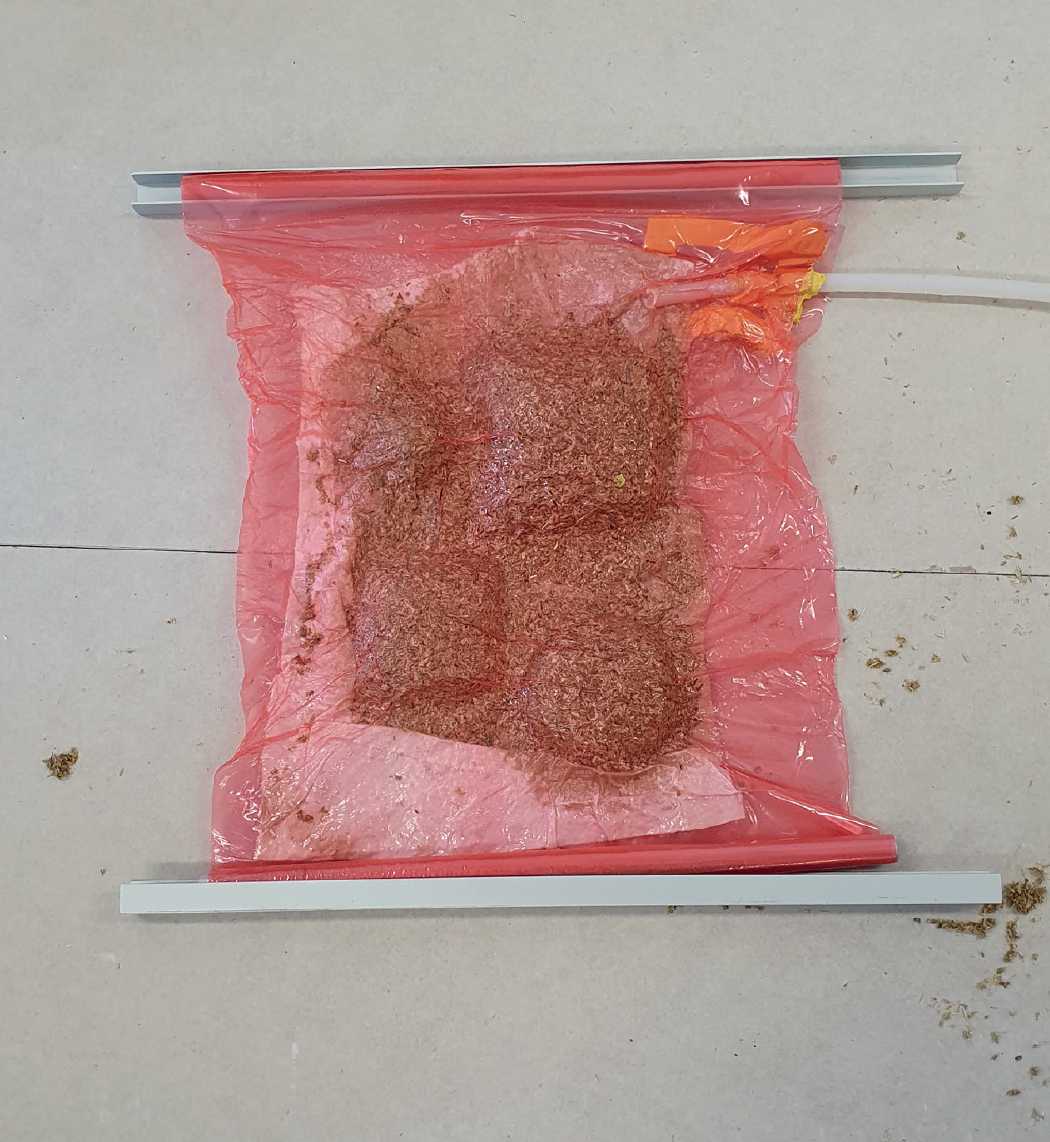

Manufacturing process

To make a mold from alfalfa, first mix 50 grams of alfalfa, 50 grams of starch and 30 grams of water to form a mixture. This mixture is then spread around the desired plaster mold, which is sealed with a mixture of soap and oil as a release agent. This is then carefully placed in a vacuum bag, with a fleece placed under the mold to suck out the air. The pressed and dried alfalfa mixture is then detached from the plaster mold. The pressed alfalfa body can then be further processed, for example by grinding to improve the shape. This process is well suited to the production of individual pieces, but the use of positive and negative molds would be advisable for larger quantities. Optimizing the oven could also shorten baking times. There is still room for improvement, but the process already enables successful production.

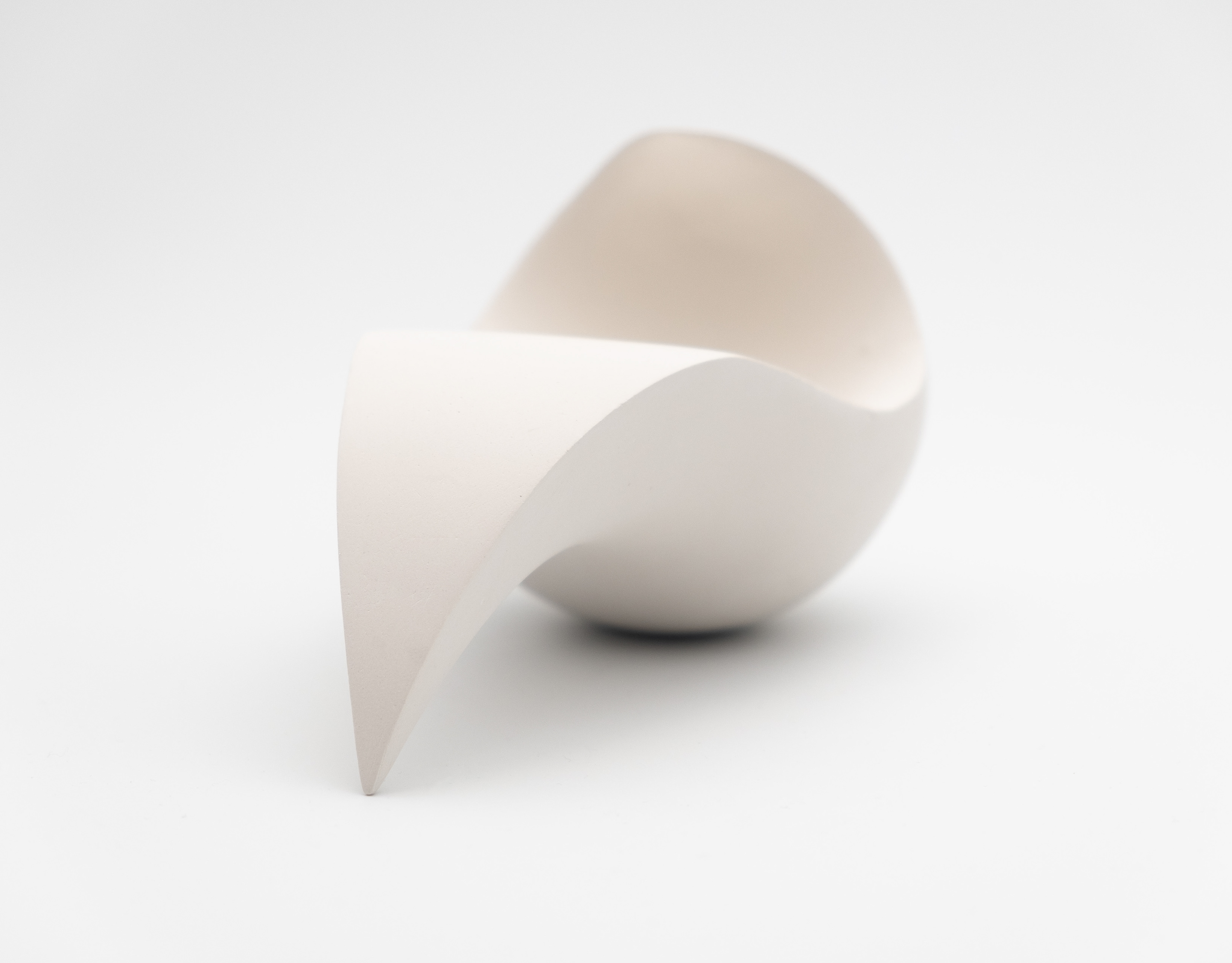

Implementation in the design

During the process, the design was inspired by leaves, in particular the Victoria Amazonica water lily, which served as the basis for the shape of the tea light. The leaf veins were mimicked by ribwort plantain, a reinforcing natural fiber, which was inserted into the hole of the plaster mold to increase stability and serve as a wick. The plaster mold was wetted with release agent, a layer of alfalfa was placed over the stems and then the whole thing was pressed and dried. Several tests were conducted and new insights were gained from each step so that the process could be iteratively improved. Although there were some problems with the vacuum bag and the bonding of the natural materials, the third trial proved to be the most successful. This was mainly because the natural material was changed again and the mushroom residue king oyster mushroom was used, as it offered greater strength and better post-processing options.

Application scenario

After sanding, beeswax was melted and poured into the mold. The plantain stalks should be well positioned in the middle to serve as a wick later. Once the wax had hardened again, the completely biodegradable tea light was ready. Now the candlelight can be enjoyed in the great outdoors while camping or at a festival in the countryside with atmospheric and sustainable light without harming nature and leaving behind waste.

WORKED WITH

Institut für Holzstofftechnik der TU Dresden

academic year

2 BA

course title

Experimentelle Fortbildung